Lujia adhesive to help you solve the common problems and solutions of high temperature resistant particle-free vacuum suction plastic!

01

glue gun is not smooth or blocking gun

FAQ:

1. Glue forms a film at the muzzle;

2. The glue in the spray gun forms a film to block the glue channel in the gun

3. Insufficient air pressure;

4. Glue has impurities;

5. Glue particles are too thick or too thick and sticky;

6. The spray gun is aging;

Solution:

1,piercing the muzzle with a wire or scraping the muzzle film with a nail;

2,often disassemble the spray gun for cleaning.,is washed with a spray gun every day and soaked in water.

3,Increase the air pressure;

4,filter glue or change glue;

5. Replace glue;

6,change the spray gun;

02

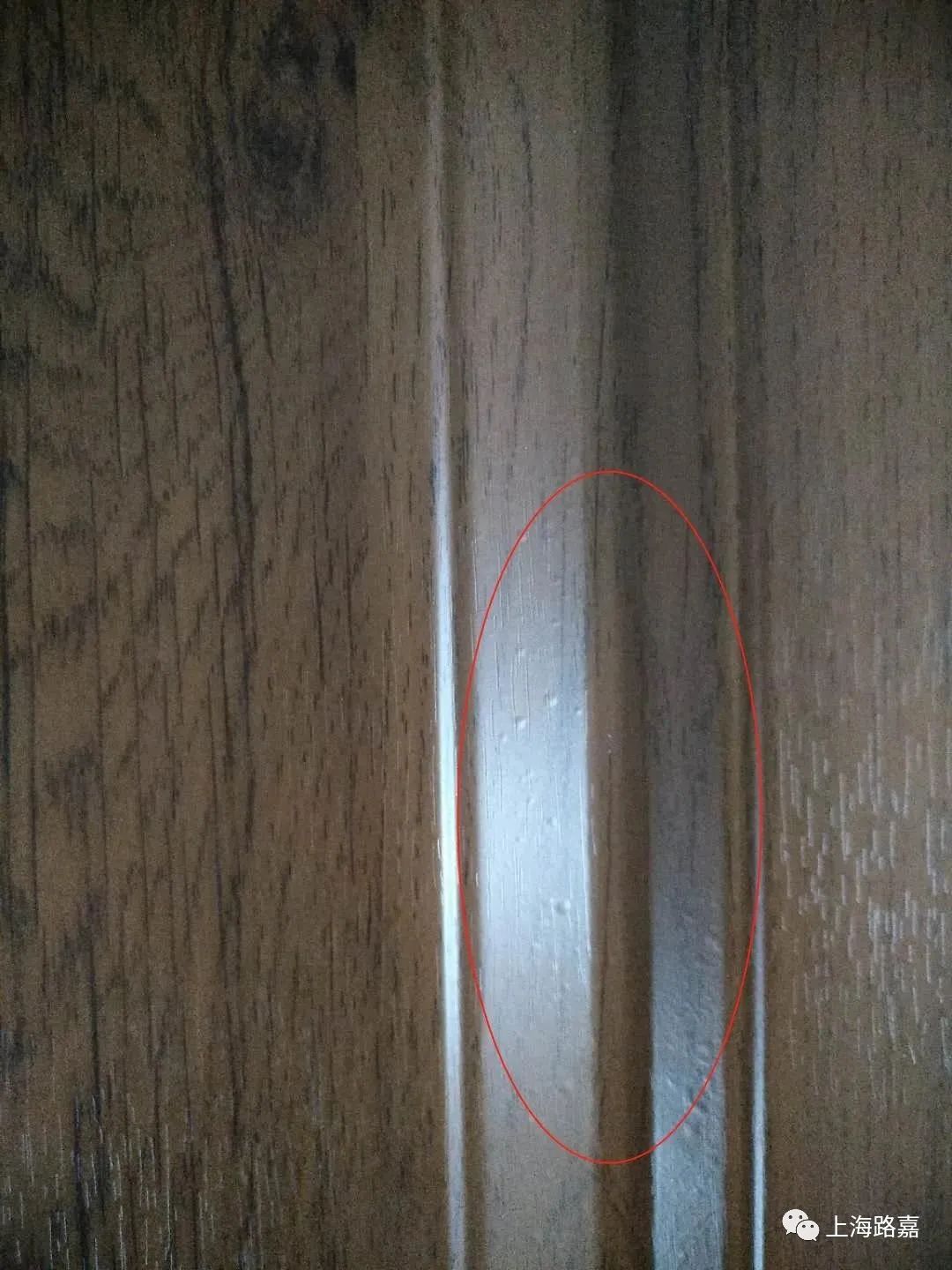

pocketing

FAQ

1. There is a lot of dust in the workshop;

2. There is dust on the back of the film;

3. Fiberboard powder;

4, spray too much glue, glue accumulation;

5. Spraying too much glue causes the fibers on the panel to absorb too much water and the fibers swell and stand upright;

6. Glue particles are too thick or too thick;

7. Glue has impurities.

solution

1. Improve the workshop environment;

2. Wipe clean with cloth or blow clean with air gun before coating;

3. Blow off the powder with an air gun before spraying glue;

4. Reduce the amount of glue sprayed;

5. Reduce the amount of glue sprayed;

6. Use plates with high fiber density;

7. Replace the glue.

03

Edge closure is not in place

FAQ:

1. The backing plate is too large;

2. Insufficient glue spraying

3. The temperature of the machine is too low and the glue is not fully activated;

4. Insufficient vacuumization results in inadequate blister packaging;

5. The initial adhesion of glue is not good;

Solution:

1,reduction pad;

2. Increase the amount of glue sprayed

3. Increase the machine speed;

4. Increase the vacuum;

5. Replace glue;

04

blistering

FAQ:

1. Insufficient glue spraying or uneven glue spraying;

2. False adhesion occurs when the activation temperature is too low.

3. Blister products are exposed to the sun or high temperature before the maintenance period;

4. The glue has poor temperature resistance;

Solution:

1,increase the amount of glue spray;

2. Increase the activation temperature

3. The cost of the product after blister is 12 hours and the product will be shipped.;

4. Add curing agent or improve the heat resistance of glue;

05

can't suck or shrink while

FAQ:

1, glue activation is not sufficient, false adhesion;

2. Insufficient glue spraying, not tight

3. The temperature resistance of glue is too poor;

4. The initial adhesion of the glue is not good, and the film shrinks during the cooling process after plastic absorption;

Solution:

1,Increase the temperature of the machine and prolong the blister time;

2. Add the amount of glue sprayed

3. Replace the glue to improve the temperature resistance of the glue;

4. Replace the glue to improve the initial viscosity of the glue;

06

glue opening

FAQ:

1. False adhesion occurs due to insufficient activation;

2. Insufficient glue spraying, not tight

3. The glue is not sticky enough;

4. Glue has poor high temperature resistance or low temperature resistance;

Solution:

1,Increase the temperature of the machine and prolong the blister time;

2. Add the amount of glue sprayed

3. Replace glue;

4. Replace glue;

Shanghai Lujiahigh temperature resistant particle-free vacuum suction plastichas no orange peel, no pitting, and good appearance.

pointis watchingyou 'd better watch it